PROCESS WEIGHING

Compact, economical and easy to install, flexible connectivity options make these terminals easy to integrate into industrial processes Industrial Process Terminals are compact, economical, easy-to-install and easy-to-use. These weighing terminals are available in multiple enclosure to match your process environment. The variety of intefaces they offer makes them easy to integrate with process control equipment. These is used in Tank / Vessel / Reactor/ Hopper / Blender Weighing. Capacity from 50 kg to 200 Tons.

VESSEL WEIGHING & BATCHING

Features :

Horizontal and Vertical Tanks / Vessel / Reactor / Hopper / Blender weighing.

Horizontal and Vertical Tanks / Vessel / Reactor / Hopper / Blender weighing.

Capacities from 50 kg. to 200 ton.

Capacities from 50 kg. to 200 ton.

Horizontal and Vertical Tanks.

Horizontal and Vertical Tanks.

Batching and Flow metering.

Batching and Flow metering.

Gain-In-Weight or Loss-In-Weight or Flow measurement.

Gain-In-Weight or Loss-In-Weight or Flow measurement.

Models suitable for Safe & Hazardus area installations.

Models suitable for Safe & Hazardus area installations.

Range of Electronic Indicators to meet process control requirements.

Range of Electronic Indicators to meet process control requirements.

Multi Channel batching (up to 8 channels).

Multi Channel batching (up to 8 channels).

Extensive communication support-serial, analogue, ethernet, fieldbus, modbus, profibos.

Extensive communication support-serial, analogue, ethernet, fieldbus, modbus, profibos.

Range of loadcells & mounting assemblies to meet tank profiles.

Range of loadcells & mounting assemblies to meet tank profiles.

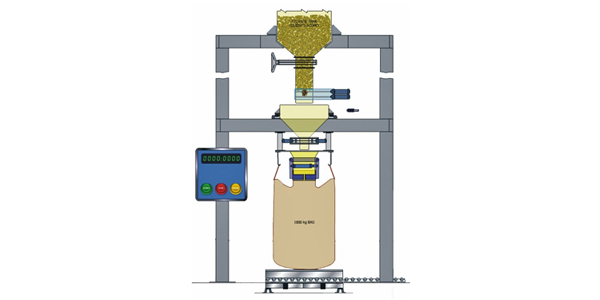

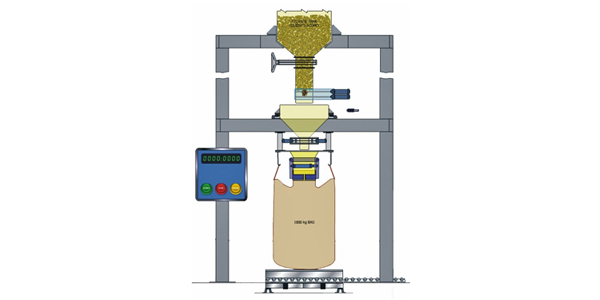

BAG FILLING SYSTEM

Features :

Filling for free flowing Powder/Granules.

Filling for free flowing Powder/Granules.

Suitable to fill 25 Kg/50 Kg.

Suitable to fill 25 Kg/50 Kg.

Jumbo Bag filling for 500 Kg/1.5 Tons.

Jumbo Bag filling for 500 Kg/1.5 Tons.

FFeeding by Slide Gate/Butterfly Valve or Screw feeder.

FFeeding by Slide Gate/Butterfly Valve or Screw feeder.

Facility to fill one dump or multi dump.

Facility to fill one dump or multi dump.

Available MOC: MS/SS in weatherproof & flameproof.

Available MOC: MS/SS in weatherproof & flameproof.

Printout of Batch Result.

Printout of Batch Result.

Optionally available sealing/stitching machines with/without conveyors.

Optionally available sealing/stitching machines with/without conveyors.

LOSS-IN-WEIGHT DOSING

Features :

Field selectable cylinder capacity.

Field selectable cylinder capacity.

Digital output for coarse and fine.

Digital output for coarse and fine.

Simultaneous display of weight, target weight and current status.

Simultaneous display of weight, target weight and current status.

Built in titalizer.

Built in titalizer.

Facility to enter tare weight.

Facility to enter tare weight.

Digital output for coarse and fine.

Digital output for coarse and fine.

Built intimer to safe guard against accidental over filling.

Built intimer to safe guard against accidental over filling.

Manual and semi auto modes.

Manual and semi auto modes.

Optional certified IS keyboard for Total weight entry.

Optional certified IS keyboard for Total weight entry.

Upto 8 nos. field configurable digital outputs.

Upto 8 nos. field configurable digital outputs.

CMRI/CCOE approved system to use in zone 1, Group IIA and IIB.

CMRI/CCOE approved system to use in zone 1, Group IIA and IIB.

BELT / CONVEYOR WEIGHING

Features :

Field selectable cylinder capacity.

Field selectable cylinder capacity.

Digital output for coarse and fine.

Digital output for coarse and fine.

Simultaneous display of weight, target weight and current status.

Simultaneous display of weight, target weight and current status.

Built in titalizer.

Built in titalizer.

Facility to enter tare weight.

Facility to enter tare weight.

Digital output for coarse and fine.

Digital output for coarse and fine.

Built intimer to safe guard against accidental over filling.

Built intimer to safe guard against accidental over filling.

Manual and semi auto modes.

Manual and semi auto modes.

Optional certified IS keyboard for Total weight entry.

Optional certified IS keyboard for Total weight entry.

Upto 8 nos. field configurable digital outputs.

Upto 8 nos. field configurable digital outputs.

CMRI/CCOE approved system to use in zone 1, Group IIA and IIB.

CMRI/CCOE approved system to use in zone 1, Group IIA and IIB.

SOLUTIONS FOR THE STEEL INDUSTRY

Features :

More than 50 years of experience in advanced measurement and control solutions for the steel / Metal industry.

More than 50 years of experience in advanced measurement and control solutions for the steel / Metal industry.

Custom designed and special loadcells built for steel applications, capacities upto 40 MN.

Custom designed and special loadcells built for steel applications, capacities upto 40 MN.

High accuracy, multichannel instrument ( upto eight synchronous measurement channels ) with most fieldbus options capability plus Ethernet.

High accuracy, multichannel instrument ( upto eight synchronous measurement channels ) with most fieldbus options capability plus Ethernet.

Special one-off designs to solve particular applications.

Special one-off designs to solve particular applications.

Application :

Weighing Systems for : Coke plant, Mineral – Blast furnace, Torpedo, Laddle Furnace, Crane, Alloy Additions, Tundish, Coil, Billet, Scrap and Delivery.

Weighing Systems for : Coke plant, Mineral – Blast furnace, Torpedo, Laddle Furnace, Crane, Alloy Additions, Tundish, Coil, Billet, Scrap and Delivery.

Roll Force measurement system for Rolling Mill.

Roll Force measurement system for Rolling Mill.

Billet Length Optimization system for continuous caster line.

Billet Length Optimization system for continuous caster line.

Crane weighing system for Laddle Transfer cranes.

Crane weighing system for Laddle Transfer cranes.

Strip Tensiometer for Holt / Cold and Galvanizing lines.

Strip Tensiometer for Holt / Cold and Galvanizing lines.

Web Tension measurement in Dynamic Resultant force measurement in any direction.

Web Tension measurement in Dynamic Resultant force measurement in any direction.

SOLUTIONS FOR PAPER INDUSTRY

Reel Optimizing System (ROS)

Improves the reel quality and reduces the waste of paper caused by reel chandes

Improves the reel quality and reduces the waste of paper caused by reel chandes

2-4% savings in paper. Eliminates bottom breaks, surface breaks and reduces turn-up breaks.

2-4% savings in paper. Eliminates bottom breaks, surface breaks and reduces turn-up breaks.

Gentle control forces protect the machinery.

Gentle control forces protect the machinery.

Disc Gap Control System:

Keeps the disk gap constant in disc refiners even at considerable force variations

Keeps the disk gap constant in disc refiners even at considerable force variations

Rider Roll System:

Continuously sets the most efficient line pressure between the carrier rolls and the paper reel.

Continuously sets the most efficient line pressure between the carrier rolls and the paper reel.

WEB TENSION CONTROL

Features :

Used in all sections of the paper machines, coating and laminating machines, Felts, Dryers, super calendars, winders, rewinders, strip steel mills, mining conveyors.

Used in all sections of the paper machines, coating and laminating machines, Felts, Dryers, super calendars, winders, rewinders, strip steel mills, mining conveyors.

Simple installation & calibration in both new and old machines.

Simple installation & calibration in both new and old machines.

Measurement in the direction of the force. Not limited to horizontal or vertical component of force.

Measurement in the direction of the force. Not limited to horizontal or vertical component of force.

Load cells capacity from 100 N to 2000 KN. Sealed to IP67. Temperature compensation up to 100 Deg C.

Load cells capacity from 100 N to 2000 KN. Sealed to IP67. Temperature compensation up to 100 Deg C.

High speed (up to 20K Hz) and multi channel (up to 8 channels) instrument supports multi line Web Tension measurement and control. Any combination of eight single zone machines up to eight zones on a single machine. Provides left, right and total tension of each zone.

High speed (up to 20K Hz) and multi channel (up to 8 channels) instrument supports multi line Web Tension measurement and control. Any combination of eight single zone machines up to eight zones on a single machine. Provides left, right and total tension of each zone.

PROCESS WEIGHING MODULE

Features :

Special load cells with moveable load points.

Special load cells with moveable load points.

Eliminates the need for expensive mechanical supports and reduces effect of thermal expansion of support structure.

Eliminates the need for expensive mechanical supports and reduces effect of thermal expansion of support structure.

Insensitive to side loads. Important for application when structure deflection or wind load are present and allow process vessels to be weighed while agitated.

Insensitive to side loads. Important for application when structure deflection or wind load are present and allow process vessels to be weighed while agitated.

Simple installation of load cells.

Simple installation of load cells.